Explorer Pipeline Gilcrease Expressway Relocation

Project Scope Explorer Pipeline was directed by the Oklahoma Turnpike Authority to relocate a portion of their 28 inch pipeline in the western portion of Tulsa County in Oklahoma due to the proposed construction of a new tollway. The project consisted of two conventional bores under West 41st Street South and under the existing Gilcrease…

Hunt Oil Burnett Ranch CO2 Flood Facilities

Project Scope Hunt Oil Co. installed a recycle compression facility consisting of dehydration, compression and pumping equipment necessary for the injection of CO2 into an existing waterflood area of the Burnett Ranch near Knox City, Texas in order to enhance oil recovery. Three existing central tank batteries were upgraded, and one new central tank battery…

Kinder Morgan Wild Basin Offload Facility

Project Scope Kinder Morgan’s Wild Basin facility is a high BTU natural gas and NGL delivery point from their Bakken gathering system to an Oasis Midstream gas processing plant. The facility was designed to accept 55 MMSCFD of 2 phase natural gas. The product was stabilized by flashing in a 2 stage process to deliver…

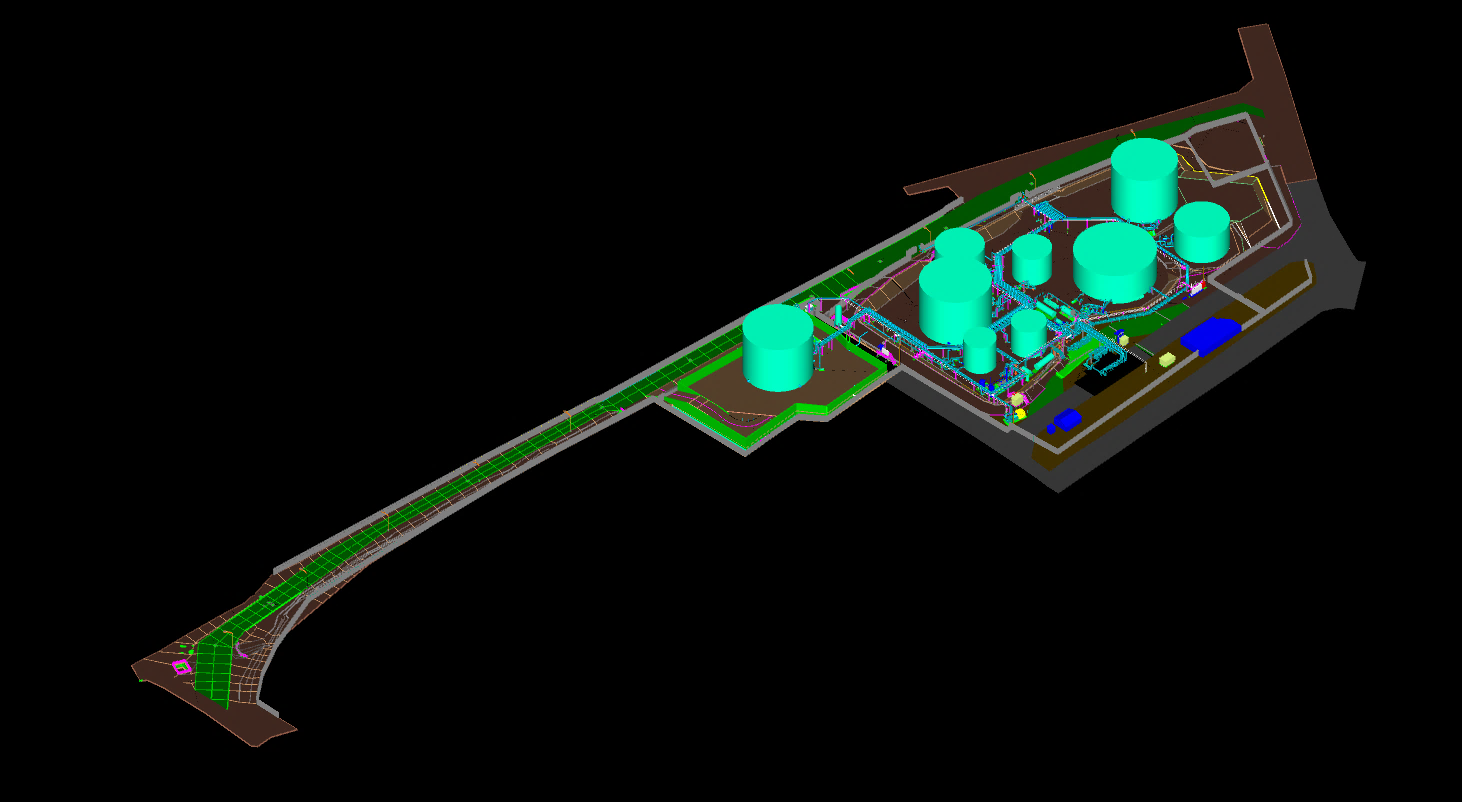

Magellan Midstream Nashville l Expansion

Project Scope Nashville I Expansion Project was executed by Magellan Midstream Partners to expand their existing facility to meet the increased demand of the local market. A new 6-arm truck loading bay was added to the existing truck loading rack to increase the terminal throughput by 60%. Ten centrifugal pumps, a 60k BBL API 650…

Powder Springs Logistics Atlanta Terminal

Project Scope Powder Springs Logistics is a joint venture formed between Magellan Midstream and Colonial Pipeline. A new facility, named Greenfield, was constructed on a 60 acre property adjacent to an existing Colonial Pipeline asset and now houses North America’s two largest spherical pressure vessels. The greenfield facility’s main objectives were to offload, store, and…

Energy Transfer Partners Ambia Compressor Station

Project Scope The project was initiated to upgrade the electrical system for the Ambia compressor station located in Ambia, IN. The facility has four gas-driven reciprocating compressors with ancillary motor loads, multiple building loads and a facility emergency generator. The facility was constructed in the 1960’s, and most of the electrical equipment in the compressor…

Williams Bluestem Conway Pump Station

Project Scope The Conway pump station is used to move NGL products from an existing Conway facility to a 3rd party via a new 190 mile 16” pipeline. The site is designed to be unmanned, monitored, and controlled remotely from the Williams Tulsa Pipeline Control Center. The Conway pump station consists of two parallel electric…

American Castings Foundry Grounding Study

Project Study Excellence conducted a grounding study of the 13.8 kV Substation Area. The process began by providing on-site soil resistivity tests for the 13.8 kV substation area using a Fluke 1625 Earth/Ground Tester to perform 4-Point Wenner Soil Resistivity Method testing. Next, we provided ground resistance testing and evaluation for the existing ground system. …

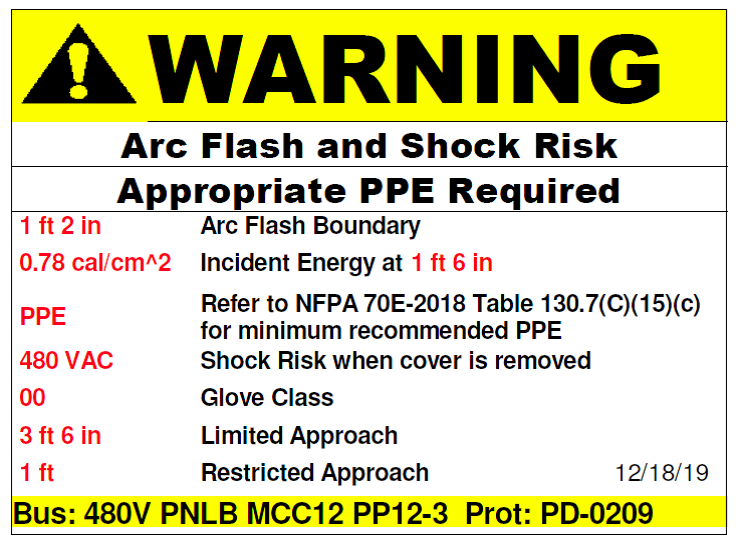

General Project Arc Flash Studies

The objective of an Arc Flash Study is to identify the arc flash hazard level for all major electrical equipment on a service or system. A completed Arc Flash Study is issued to the client with Arc Flash Labels to be installed on pertinent electrical devices. The labels include information regarding arc flash energy and…

Explorer Pipeline Fauna Facility Upgrade

Project Scope The Fauna Facility Upgrade Project in Houston, Texas consisted of two phases, both of which centered on optimizing the tank to mainline flow. Phase I installed new piping from an existing surge relief system to the suction side of two existing mainline units. A new turbine meter, small volume prover, and new piping…

Explorer Pipeline Fauna Fire Water System FEED

Project Scope The Fauna Fire Water System FEED study was completed to determine the design perimeters and equipment necessary to reduce the risk of multiple tank fires due to radiant heat from an adjacent tank fire if one was to occur. Excellence was tasked with determining which tanks are at risk and to prepare options…

General Project Facility GAP Analysis Services

Project Scope Excellence Engineering provides Facility GAP Analysis to clients in order to identify NFPA 70 (NEC), Article 501 (liquids and vapors) and Article 502 (dusts) code deficiencies in relation to the defined electrical area hazardous classification of petrochemical and oil & gas related facilities. This type of analysis is beneficial in both new and…

General Services – Hazardous Area Classification Study

Project Scope Excellence Engineering provides hazardous area classification studies for petrochemical, refinery, midstream and all other oil & gas related facilities. The purpose of the Hazardous Area Classification Study is to define the hazardous area for the installation of mechanical, electrical and control system equipment. The analysis is performed utilizing the facility material balance, process…

Hess Tioga Crude Storage Expansion

Project Scope Addition of two 70,000 BBL IFR crude oil storage tanks at the Hess Tioga Rail Loading facility. Civil, mechanical, and electrical engineering design, programming, and commissioning. Project included piping, electrical, instrumentation, automation, and fire water and foam systems. Notable Accomplishments & Challenges Upgraded existing fire systems and seamlessly integrated upgraded automation and control…

Hess Tioga NGL Storage And Rail Loading

Project Scope The Hess Tioga NGL rail loading facility is a 16-spot rail loading rack on a spur of the Tioga crude rail loop. It loads propane, butane, and natural gasoline produced and fractionated at the Tioga Gas Plant located 3 miles away. Loading rack is connected to the plant outlet by 8” and 6”…

Holly Frontier Corporation West HVGO Tank 188 Truck Loading

Project Scope HollyFrontier’s Truck Loading project in Tulsa, Oklahoma implemented an additional means of removing heavy gas oils (HVGO) from storage tank 188 in order to supplement the existing piping discharge. The project added a single truck loading spot with a 15HP/460V product transfer pump, truck grounding monitor, local pump control station and ESD, local…

Holly Frontier Corporation Gas Compressor Starter Replacement

Project Scope The objective of the J-50 Wet Gas Compressor Starter Replacement Project was to replace the obsolete and antiquated 13.8kV, 5600HP reduced voltage reactor starter used to start and run the wet gas compressor of HollyFrontier’s fluid catalytic cracking unit (FCCU). Replacement components for the existing Westinghouse air-break circuit breakers and starting reactor that…

Holly Frontier Corporation Substation 2 Relay Replacement

Project Scope The Substation 2 Mechanical Relay Replacement Project was initiated to replace two antiquated oil-immersed 2300V circuit breaker switchboard control panels at the HollyFrontier Refinery West Plant. The location of the switchboard panels inside the substation had become a concern due to the potential arc flash hazard to refinery personnel from the overhead open…

Kinder Morgan Arc Flash Study

Project Scope The group of projects were executed to bring compressor station upgrade projects into compliance with NFPA 70E. Excellence provided a field survey to gather site information to analyze the installed electrical system which included circuit breakers, motor starters, panelboards, motor control centers, transformers, feeder and incoming line cables, and other wire and cable…

Magellan Midstream Partners Albany Tank And Butane Offloading

Project Scope Magellan Midstream’s Albany facility was upgraded to increase the storage capacity of gasoline, increase the throughput of the existing truck rack, and to provide blending capabilities to the terminal. A new 100,000 barrel tank was added to increase the storage capacity of the terminal. Three new pumps were added to the existing system…

Magellan Midstream Partners Allen Blending Expansion

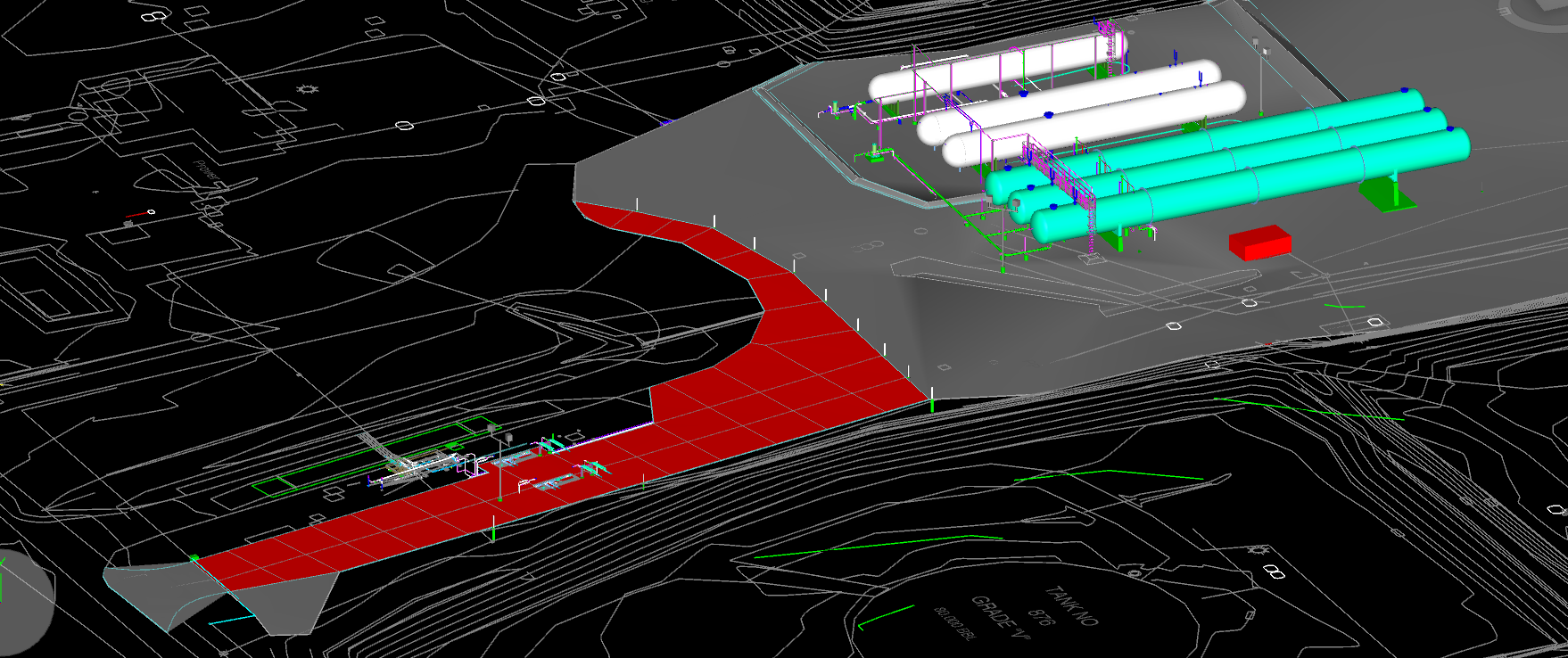

Project Scope Magellan Midstream initiated the Blending Expansion project in Allen, OK to increase blending capabilities to match new pipelines rates. The project consisted of three new 107,000 gallon horizontal butane storage vessels, two additional offloading spots, and two new VFD controlled vertical can pumps to increase the injection rates for both natural gasoline (w-grade)…

Magellan Midstream Dupont Terminal Upgrade

Project Scope The Dupont Terminal Upgrade project was formulated to add rail offloading, truck loading and offloading, storage, and system blending capabilities to the facility. Excellence Engineering was involved in the project from FEED through As-Builting which spanned from May 2015 to April 2019. A nitrogen generation system, consisting of three 250 HP compressors, was…

Magellan East Houston Butane Storage

Project Scope Expansion of butane storage and terminal capacity to support blending the new East Houston-Hearne Pipeline and inbound Galena Park pipelines. Scope included the addition of a 40,000 BBL butane storage sphere, blend pumps, meter runs and connecting piping. Project included grading, structural, piping, mechanical, electrical, instrumentation, automation, and fire water system. Notable Accomplishments…

Magellan Midstream Partners Greensboro ll Phase l & ll

Project Scope Magellan Midstream initiated the Greensboro Bullet to Tank project to increase facility blending capabilities. The blending rate for Phase I was increased by upgrading the injection system upstream of the existing Tank manifold. A new vertical can blending pump with a larger diameter pump discharge and recirculation piping were added to accommodate the…

Magellan Midstream Little Rock Bullet to Tank

Project Scope Little Rock Bullet to Tank project was tasked with moving butane from one facility to another larger facility nearby. The existing facility’s control system was not documented and required extensive as-built prior to detail design. Excellence Engineering assisted from FEED through as-built. Excellence ran hydraulic analyses to develop solutions to alleviate NPSH issues…

Magellan Midstream Partners Nashville ll Truck to Tank Blending

Project Scope The Truck to Tank project at Magellan Midstream’s Nashville II terminal was designed to add butane blending capabilities to the facility. Along with the new blending capabilities, two new pumps were installed at each of the two existing gasoline tanks to increase the throughput of the loading rack. Two diesel loading arms were…

Magellan Midstream New Haven Waterfront T2T

Project Scope The New Haven-Waterfront Truck to Tank project began as a single truck offload to a single tank. An addition of a tank mixer onto the tank revealed that there was a lack of sufficient power sources in the area for the newly premised assets. The client agreed to add a new 1200 amp…

Magellan OKC Reno Tank Mixer Addition

Project Scope The OKC Reno Terminal Mixer Addition project was initiated to improve the mixing capability of two refined product tanks. Magellan was experiencing issues working off the high RVP tops of the tanks. The higher RVP product had a tendency to stay stratified above incoming lower RVP product preventing homogenous blending of the tanks.…

Magellan Midstream Spartanburg l Truck to Tank

Project Scope Spartanburg Truck to Tank project was planned to provide a single truck location for product trucks to offload medium to the facility tanks. However, due to the confined space there were not many options for locations to install this operation. The project combined adding the offload location with the existing truck staging for…

Magellan Midstream Springfield TLR Upgrade

Project Scope Springfield Truck Loading Rack Controls Upgrade project was to increase the facilities truck throughput as well as bring the facility controls up to current company standards. The project decommissioned the existing load arm meters, PLC and IO, injection meters and Petrocount computers. Driver buildings were added to each lane to compartmentalize and speed…

NUSTAR/EOG ST. James Rail Offloading

Project Scope NuStar-EOG joint venture to deliver Bakken crude to the St. James, LA complex. Facility included a 20-spot, double sided railcar offloading facility, measurement and connecting piping. The electrical, instrumentation, and automation engineering scope included utility interface to supply power and distribution to the facility, communication interface to TopTech data management system, design of…

ONEOK NGL Pipeline, L.P. Carney Booster Station Expansion

Project Scope Oneok NGL Pipeline, L.P. expanded the thru capacity of their Carney NGL Booster Station by adding an additional 500HP, 480V, VFD controlled NGL pump and replacing the existing discharge valve. A new 12’ x 26’ electrical building was added to house a new PLC control system, single phase 120VAC UPS, 480V/2000A/3P4W switchboard, 480V/250A/3P4W…

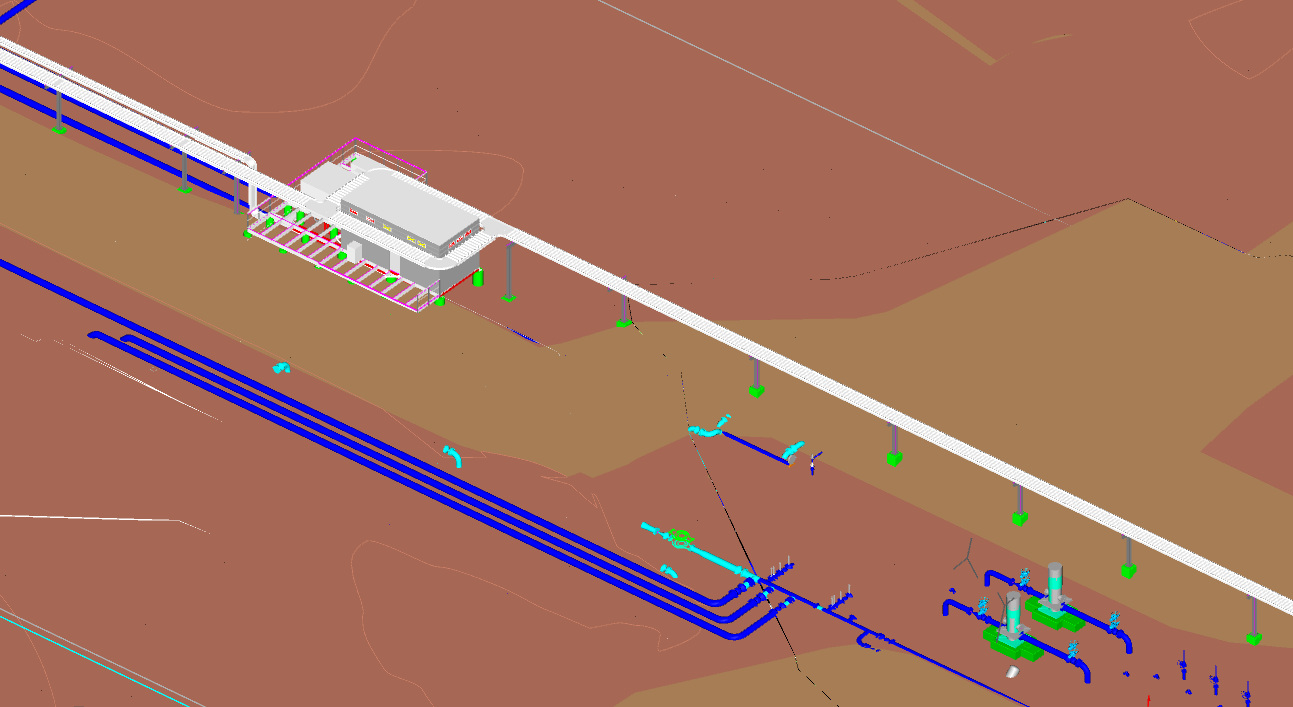

JP Energy Partners Unloading Facility & Metering Station

Project Scope JP Energy Partners planned a crude oil gathering, storage and mainline pump facility located south of Cherokee, Oklahoma and a crude oil pipeline metering station at Cushing, Oklahoma to serve the new Great Salt Plains 8” Crude Pipeline originating in Cherokee, Oklahoma and terminating in Cushing, Oklahoma. The Cherokee Crude Oil Unloading Facility…

Selas Fluid Processing Corporation GOX3000 Air Separation Facility

Project Scope Selas Fluid Processing Corporation/Linde Gas constructed a 3,000 ton/day air separation facility near Lewisville, Arkansas for the purpose of producing and selling liquefied nitrogen and liquefied oxygen. The main components of the air separation facility are a 12,000HP/13.2kV Recycle air compressor, 2,500HP/13.2kV Main air compressor, cryogenic cold box and storage for liquefied oxygen…

United States Air Force 27th Special Operations Wing

Project Scope Excellence was contracted to provide Design/Build Services for aircraft hangar electrical upgrades and aircraft battery charger room upgrades at Cannon AFB, New Mexico. The upgraded battery charging room required the design and installation of a non-load bearing wall and door, upgrading the electrical system, lighting, fire protection and notification system, dedicated HVAC and…

Magellan Midstream Standard Design – Ratio Blending

Project Scope The standard metering pump skid was requested to be a self-contained unit that would control itself to match pace with a site meter and monitor the output of product off of the skid. The skid was designed to be able to be installed at multiple locations and be flexible to meet onsite piping…

Williams/Laurel Mountain Midstream Herminie Compressor Station

Project Scope Williams/Laurel Mountain Midstream, LLC added a new two bay natural gas compressor building with one 3612 CAT driven Ariel compressor and space for a future 3612 CAT driven Ariel compressor and a new inlet slug catcher, inlet filter separator, dehydration discharge filter separator and discharge oil coalescer filter at the existing Herminie Compressor…

Velocity Midstream – SCOOP Engineering Review

Project Scope Excellence Engineering, LLC was contracted to carry out a comprehensive electrical engineering review of documentation and drawings provided by the client for the South Central Oklahoma Oil Pipeline (SCOOP) Project that was under construction in south-central Oklahoma. Excellence was also asked to provide a hydraulic analysis of the existing pipeline system along with…

Hess Tioga Crude Oil Facility – Rail Loading

Project Scope The Hess Tioga facility was a green field project that required the development of 475 acres adjacent to Tioga, ND. The primary focus of the facility was to load Bakken Crude Oil and NGLs (Propane, Butane, Natural Gasoline) onto unit trains for delivery to southern markets. The facility housed a fully automated 20…

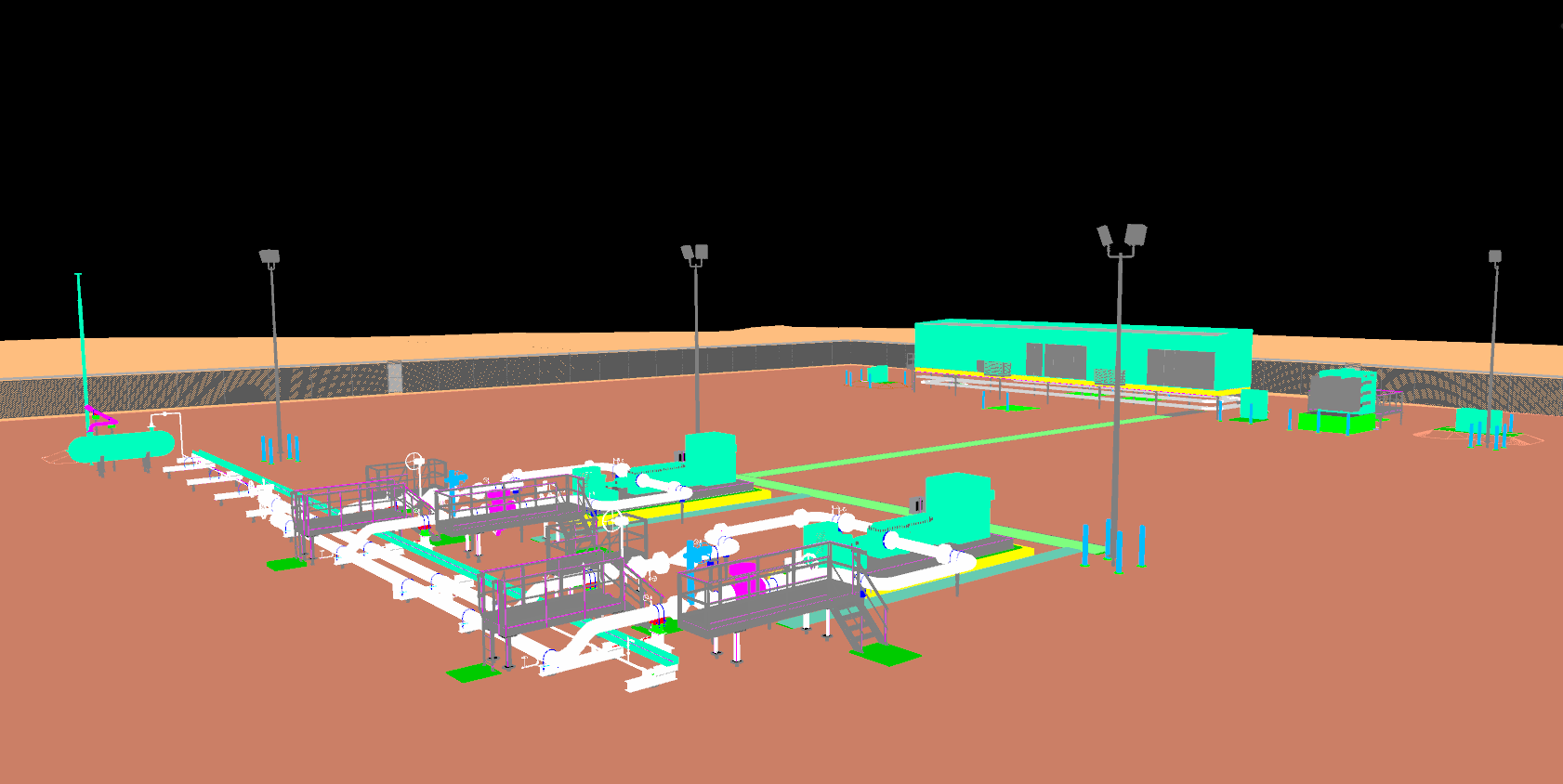

Hess Blue Buttes Compressor Station

Project Scope Blue Buttes Compressor Station was designed and developed to be an integral part of an extensive gas gathering system across North Dakota which is operated by Hess North Dakota Pipeline, LLC. Developed to increase discharge pressure and volume to the Hess Tioga Gas Plant, this Greenfield eight-compressor site produces 50 MMSCFD at an…

Cimarex Triple Crown Gathering System

Project Scope Cimarex Energy Co. has been and is continuing to develop its Triple Crown Natural Gas Gathering System after extensive drilling operations in the Wolfcamp Shale and Bone Springs Sands region of the Permian Basin. Multiple natural gas compression stations with dehydration and condensate offloading capabilities have been installed starting in 2017 and continuing…