Project

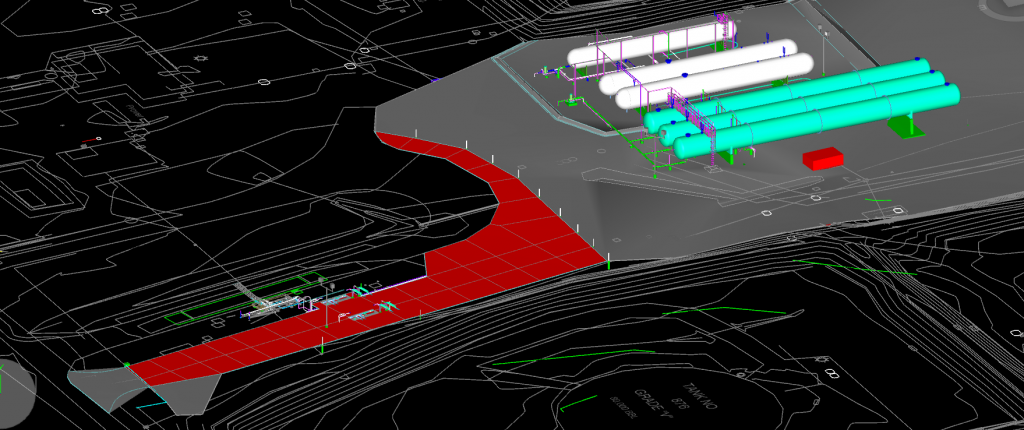

Magellan Midstream Partners Allen Blending Expansion

Project Scope Magellan Midstream initiated the Blending Expansion project in Allen, OK to increase blending capabilities to match new pipelines rates. The project consisted of three new 107,000 gallon horizontal butane storage vessels, two additional offloading spots, and two new VFD controlled vertical can pumps to increase the injection rates for both natural gasoline (w-grade)…

Read MoreMagellan Midstream Dupont Terminal Upgrade

Project Scope The Dupont Terminal Upgrade project was formulated to add rail offloading, truck loading and offloading, storage, and system blending capabilities to the facility. Excellence Engineering was involved in the project from FEED through As-Builting which spanned from May 2015 to April 2019. A nitrogen generation system, consisting of three 250 HP compressors, was…

Read MoreMagellan East Houston Butane Storage

Project Scope Expansion of butane storage and terminal capacity to support blending the new East Houston-Hearne Pipeline and inbound Galena Park pipelines. Scope included the addition of a 40,000 BBL butane storage sphere, blend pumps, meter runs and connecting piping. Project included grading, structural, piping, mechanical, electrical, instrumentation, automation, and fire water system. Notable Accomplishments…

Read MoreMagellan Midstream Partners Greensboro ll Phase l & ll

Project Scope Magellan Midstream initiated the Greensboro Bullet to Tank project to increase facility blending capabilities. The blending rate for Phase I was increased by upgrading the injection system upstream of the existing Tank manifold. A new vertical can blending pump with a larger diameter pump discharge and recirculation piping were added to accommodate the…

Read MoreMagellan Midstream Little Rock Bullet to Tank

Project Scope Little Rock Bullet to Tank project was tasked with moving butane from one facility to another larger facility nearby. The existing facility’s control system was not documented and required extensive as-built prior to detail design. Excellence Engineering assisted from FEED through as-built. Excellence ran hydraulic analyses to develop solutions to alleviate NPSH issues…

Read MoreMagellan Midstream Partners Nashville ll Truck to Tank Blending

Project Scope The Truck to Tank project at Magellan Midstream’s Nashville II terminal was designed to add butane blending capabilities to the facility. Along with the new blending capabilities, two new pumps were installed at each of the two existing gasoline tanks to increase the throughput of the loading rack. Two diesel loading arms were…

Read MoreMagellan Midstream New Haven Waterfront T2T

Project Scope The New Haven-Waterfront Truck to Tank project began as a single truck offload to a single tank. An addition of a tank mixer onto the tank revealed that there was a lack of sufficient power sources in the area for the newly premised assets. The client agreed to add a new 1200 amp…

Read MoreMagellan OKC Reno Tank Mixer Addition

Project Scope The OKC Reno Terminal Mixer Addition project was initiated to improve the mixing capability of two refined product tanks. Magellan was experiencing issues working off the high RVP tops of the tanks. The higher RVP product had a tendency to stay stratified above incoming lower RVP product preventing homogenous blending of the tanks.…

Read MoreMagellan Midstream Spartanburg l Truck to Tank

Project Scope Spartanburg Truck to Tank project was planned to provide a single truck location for product trucks to offload medium to the facility tanks. However, due to the confined space there were not many options for locations to install this operation. The project combined adding the offload location with the existing truck staging for…

Read MoreMagellan Midstream Springfield TLR Upgrade

Project Scope Springfield Truck Loading Rack Controls Upgrade project was to increase the facilities truck throughput as well as bring the facility controls up to current company standards. The project decommissioned the existing load arm meters, PLC and IO, injection meters and Petrocount computers. Driver buildings were added to each lane to compartmentalize and speed…

Read More